Warehouse Management System

Delivering Real Results

A comprehensive Tier 1 Warehouse Management System (WMS) can help you gain control of warehousing, inventory, and distribution processes to eliminate errors, automate order processing, accurately manage inventory, save valuable resources, and deliver the right product on time, the first time. Our WMS takes the chaos out of day-to-day operations, empowers faster processing of orders, provides real-time visibility, and creates the efficiency needed to streamline processes while also controlling costs. If you’re still relying on manual or paper-based processes or limited software with basic functionality, it’s time to take your operations to the next level with the Hy-Tek WMS.

Key Features

Access Information In Real-Time

Gain Control Of All Warehousing Functions

Automate Inventory & Order Processing

Optimize Asset & Labor Utilization

Robust Tier 1 Functionality

Our supply chain execution solutions offer up a feature-rich set of warehouse operational capabilities and functionalities to deliver state-of-the-art inventory control, improved material flow, and throughput, in real-time, at a comfortable price point for companies of all sizes.

Seamless, Real-Time ERP Integrations

Unified messaging across all ERP Systems. From homegrown, existing ERP, or a new ERP – our WMS can adapt to whatever ERP system you choose.

Flexible

Whatever your IT situation, we have options to fit your needs now and in the future. Our flexible yet structured system architecture is what makes all the difference.

Accelerated Implementations

Combine a proven methodology 35 years in the making with our seasoned in-house software engineering and development team, our deployments are done faster, AND better, all without the high-costs often associated with a WMS and other system implementations.

Low Total Cost of Ownership

We’re able to configure our system to your business logic without expensive modifications of source code. This means lower TCO, faster implementation, and less risk for you.

Owned, Developed & Supported 100% in USA

Our leadership, engineers and support staff personally handle every aspect of Hy-Tek solutions. It’s been the way since the company started and will remain this way.

Benefits

- Inbound shipment tracking

- Inbound dock management

- Inbound trailer and yard management

- Receiving from PO, ASN, Vendor

- Directed, Manual or Semi-Directed Put-a-way

- Location Management

- Slotting

- Material identification, Item Alias & License Plates

- Barcode & Label Management

- Moveable Unit Operations

- Receiving document support

- Customizable mobile & Automated data capture

- Returns Management & Authorization Support – customer & production

- RMA Receiving

- SOP Returns

- Site Transfers – In & Out

- Bin Transfers

- Cross-docking

- Raw Material Inventory Management

- Finished Goods Inventory Management

- Bill of Materials (BOM) Support

- Receipt from MFG Receiving – Standard Integration Point

- Real-time Inventory Status

- MFG Work Order Management

- Directed Inventory Moves to Work Cells

- Restocking

- Kitting – Completion, Teardown, Components

- Labor Utilization & Performance Reporting

- Physical Inventory & Audit Support

- Dynamic Workflow Assignment

- Cycle Counting

- Task Interleaving

- Inventory Adjustments

- Discrete Travel Calculation

- Inventory to Order Allocations

- Task Management

- Order Allocation Postponement

- Directed Move Requests

- Inventory Availability & Inquiries

- Order Processing & Entry

- Back Order Management

- Pick & Pack Support

- Hot, Top Off, Bulk Replenishment

- Product Lifecycle Management & Tracking

- Kitting & Component Value-added Services

- Lot control, Serial Number, Manufacturing Date, Expiry Dating, Shelf-life, QC Hold & Release Inventory Status

- Dynamic Pick Assignment Based on Capacity & Resource Availability

- Shipment Out Prioritization

- Advanced Picking Methodologies

- Single & Multi Order

- Voice Picking

- Zone Picking

- Wave Picking

- SKU Picking

- Batch Picking

- Bulk

- Narrow Aisle Pick

- Pick & Pass

- Cart-based picking

- Pick-to-Box / Pick-To-Carton

- Shipment Drop Sequences

- shipment Creations to Amazon

- Pick Release Staging

- Pallet/Manifest/Load Building

- Advanced Picking Methodologies

- Appointment Scheduling

- Staging Location

- Assignment

- Dock Door Scheduling

- Rules-based, System-Directed Picking

- FEFO, LIFO, LEFO, Pick to Clean, Pick to Efficiency

- Outbound Trailer & Yard Management

- Quality Check for Boxes

- Real-Time Inventory Availability & Visibility

- Advanced Cartonization Logic

- Handheld Label Printing / Print & Apply

- Box-Building, Cubing

- Documentation & Labeling

- Big Box

- Requirements

- UCC 128

- BOL

- Export

- HazMat

- Volumetrics – Cubiscan & Scale Integrations

- Advanced Picking Methodologies

- TL & Multi-Stop

- Carrier Compliant Labeling

- Custom Labeling & Pack Slips

- RFID Compliance

- ASN/EDI Integrations

- Integrated Shipping Execution – Parcel, LTI., Rate-Shopping

- Omnichannel Order Fulfillment

- Manifesting & Transportation Planning

- Wave Planning

- Shipment Task Management

- Load Planning & Execution

Looking to Integrate your Warehouse?

Improve your business operations wherever you’re at in the journey.

- Site Transfers – In & Out

- Provide Better Customer Service

- Improve Inventory Accuracy

- Maximize Asset & Resource Utilization

Real-Time Visibility

Delivers Real-Time Visibility With Instant Access To The Most Accurate Information

Allows Managers To Redeploy Resources As Needed

Tracks Process Status And Individual Performance In Real-Time

Allows Users To Identify And Measure Continuous Improvement Initiatives

Monitor And Reassign Labor To Understaffed Areas

Ensure Inbound Receipts Have Been Put Away Properly

Access Data In Any Hy-Tek System And Even From Third-Party Systems Being Used

Supports Internal And External Customer Needs

Related Solutions

ERP Integration

Transporation Management System

realtime Visibility & Reporting

Related Resources

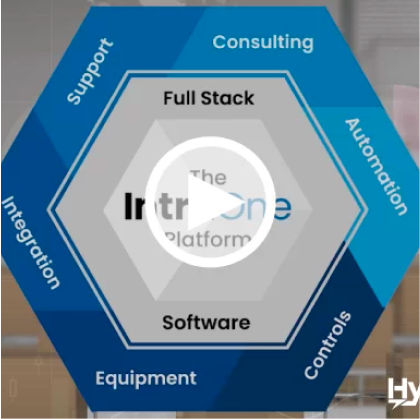

IntraOne Platform

Warehouse automation planning is crucial given that most companies are planning to invest in their supply chain in the next few years.

Warehouse Automation Planning: Lead Time Challenges & How to Overcome Them

Warehouse automation planning is crucial given that most companies are planning to invest in their supply chain in the next few years.

Warehouse KPI Metrics: Every Single One Under the Sun

No matter what kind of warehouse you run, there are key performance indicators (KPIs) that you should be tracking to measure success.