Storage

Warehouse Storage Solutions That Maximize Available Space

The way products and material are stored in a warehouse or fulfillment operation heavily impacts efficiency and productivity.

ith data and technology analysis, our experts can identify the proper storage systems and slot items into optimal picking locations.

This minimizes retrieval time, boosting productivity. Efficient storage solutions maximize available space, saving costs and resources while accommodating more inventory without expanding physically.

Types of Storage

Utilize free space overhead of operators with a carton delivery system routed throughout all picking areas and levels of your warehouse.

Reserve Storage

Active Storage

Storage Solutions

Static Rack

Pick Modules & Structures

Talk to an Engineer

Get in touch with a Hy-Tek expert to discuss solutions that will optimize your retail operations.

Related Resources

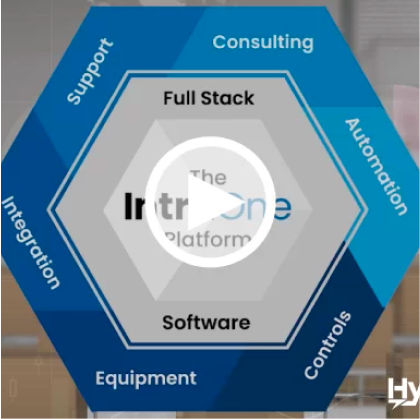

IntraOne Platform

Warehouse automation planning is crucial given that most companies are planning to invest in their supply chain in the next few years.

Warehouse Automation Planning: Lead Time Challenges & How to Overcome Them

Warehouse automation planning is crucial given that most companies are planning to invest in their supply chain in the next few years.

Warehouse KPI Metrics: Every Single One Under the Sun

No matter what kind of warehouse you run, there are key performance indicators (KPIs) that you should be tracking to measure success.