Warehouse Control Systems

Experience Unmatched Modularity & Scalability

Whether you need more control or better control of your material handling systems, the Realtime360 Warehouse Control System™ offers you a complete WCS solution. From sortation and in-motion weighing to label print and apply and PLC controls, our solution offers both the modularity and scalability to fit your needs, coupled with the most user-friendly HMI available.

Key Features

Fully Compliant With All Industry Standards From The Floor To The Host System

IT Friendly, Database-Driven Software Application At The Core Of The System

Scalable, Email Alerts, Front-End Graphics, Tablet Friendly

Remotely Accessible Web-Based Reporting

Need better control of your system? Improve your business operations with the modularity and scalability you need.

This introductory eBook discusses crucial warehouse software to help you optimize your warehouse space, reduce inventory costs, increase order fulfillment rates, avoid stockouts, and more.

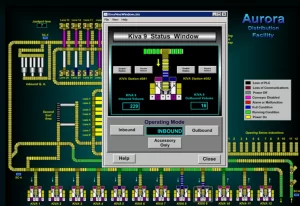

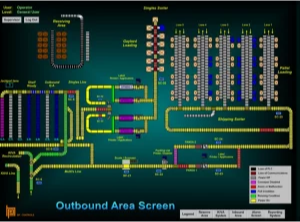

HMI & Diagnostics Reporting

Innovative HMI (human-machine interface) based on CAD layout of your systems provides a user-friendly GUI (Graphical User Interface) that enables easy set-up and operation

Easy adjustment of multiple operational parameters. HMI provides a real-time view of each material handling system.

Real-time view of WCS systems. Color-coded operational status for easy troubleshooting and quick problem resolution.

Provides easy to understand diagnostics and reports on system performance.

Specific Items Monitored*:

- Status of each electrical panel (Emergency-Stop, Power and Overload faults)

- Battery condition from each PLC (Normal, Low)

- PLC status (Major Faults, Scan Time, Rack Conditions)

- Air Pressure status from each compressor (Normal, Low)

- Motor overload status by panel

- Jams, Full Lines and Emergency-Stop Status by panel

- Individual Full Line and Jam Photoeye Status

- Individual Emergency-Stop Pushbutton/Lanyard Status

- Total Cartons Scanned

- Total Cartons Confirmed

- Total Reject Count

- Percentage of Valid Reads

Realtime360 View is built upon our standardized software platform and tailored to the various systems being monitored. Because it is configured specifically for each application, all functionality described above may not be included in your system.

Related Solutions

Warehouse Execution System

HMI and diagnostics

Automation Control System

Let’s Get to Work!

Schedule a Demo

Meet With A Hy-Tek Expert To Start Planning Your Journey Into Automation.

Installation & Support Services

We Work Directly With You Through The Planning, Installation & Beyond To Provide The Right Services At The Right Time, 24/7, 365.

Related Resources

IntraOne Platform

Warehouse automation planning is crucial given that most companies are planning to invest in their supply chain in the next few years.

Warehouse Automation Planning: Lead Time Challenges & How to Overcome Them

Warehouse automation planning is crucial given that most companies are planning to invest in their supply chain in the next few years.

Warehouse KPI Metrics: Every Single One Under the Sun

No matter what kind of warehouse you run, there are key performance indicators (KPIs) that you should be tracking to measure success.

Warehouse Execution System FAQs

General

A Warehouse Control System (WCS) is operational software that connects various automated systems like conveyors, sorters, Automated Storage and Retrieval systems (AS/RS) and Pick/Put to Light. The WCS communicates data to the controllers, typically Programmable Logic Controllers (PLCs), and triggers its operation to support material flow through the distribution center’s warehouse(s).

A Warehouse Execution System (WES) is built around performance optimization software that sits between the client’s Warehouse Management System (WMS) and includes all the functionality of a WCS. However, the WES uses sophisticated algorithms to leverage real-time inputs from all “islands of automation” including order finishing, manifesting and other sources, as well as data from inventory, order, labor, transportation and other activities. A WES will optimize a distribution center’s activity and dynamically manage it throughout all processes.

A WES includes a variety of options that are easily configured during installation. This allows users to utilize only the functionality they need and implement new functionality when it becomes necessary for growth or to accommodate changes in material flow. The ideal WES integrates all commercially available WMS brands from any provider and includes built-in control capability to interface with any semi or fully automated material handling systems.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts.

Common

A Warehouse Control System (WCS) is operational software that connects various automated systems like conveyors, sorters, Automated Storage and Retrieval systems (AS/RS) and Pick/Put to Light.

A Warehouse Control System (WCS) is operational software that connects various automated systems like conveyors, sorters, Automated Storage and Retrieval systems (AS/RS) and Pick/Put to Light.

A Warehouse Control System (WCS) is operational software that connects various automated systems like conveyors, sorters, Automated Storage and Retrieval systems (AS/RS) and Pick/Put to Light.

A Warehouse Control System (WCS) is operational software that connects various automated systems like conveyors, sorters, Automated Storage and Retrieval systems (AS/RS) and Pick/Put to Light.

A Warehouse Control System (WCS) is operational software that connects various automated systems like conveyors, sorters, Automated Storage and Retrieval systems (AS/RS) and Pick/Put to Light.

A Warehouse Control System (WCS) is operational software that connects various automated systems like conveyors, sorters, Automated Storage and Retrieval systems (AS/RS) and Pick/Put to Light.

A Warehouse Control System (WCS) is operational software that connects various automated systems like conveyors, sorters, Automated Storage and Retrieval systems (AS/RS) and Pick/Put to Light.